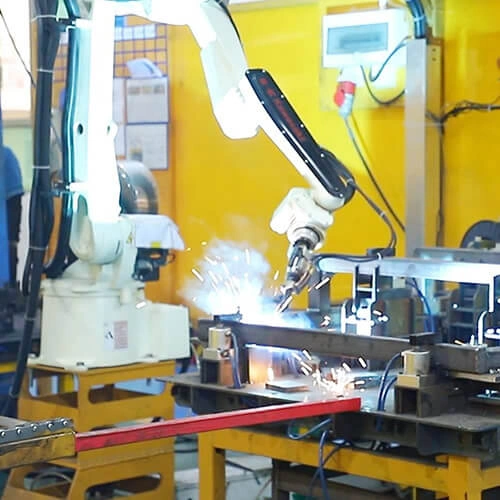

Market leader

Trusted global provider of precision manufacturing solutions.

-

25+ surface finishes, 100+ processing technology

-

Social responsibility: Practice low-carbon, build an environmental protection park, and build a better future

-

Efficient logistics: Efficient and reliable logistics support covering the world

All customer information is secure and confidential

Partner