● ISO 13458、3834

● IATF16949

● ASME

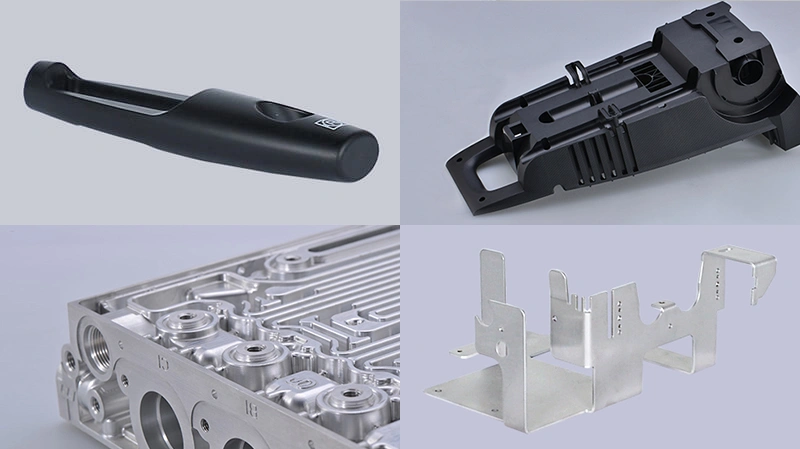

Mill-turn composite machining center, standard 3-axis, continuous 5-axis, 3+2 axis milling machine, drilling and post-processing

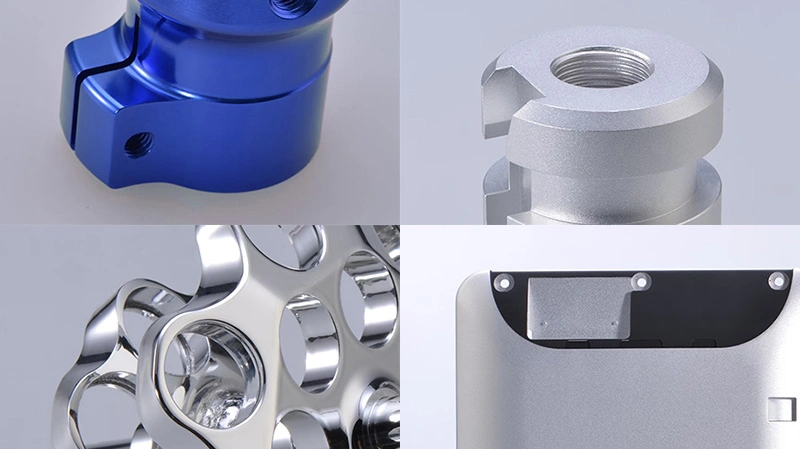

More than 50 types of materials and over 12 surface treatments;

Machining accuracy: ±.0000394in (0.001mm ),equipped with a high-precision inspection center of 1.5um grade

Laser, plasma and water jet cutting, hole machining, bending, stretch forming,metal spinning

40t-750t stamping equipment, agv, mig and tig welding

Size range: 0.19*0.19*0.011in - 51.18*78.7*15.74in (5*5*0.3mm - 1300*2000*400mm)

Computer-aided engineering(cae), design for manufacturing(dfm), stack mold, 2k injection molding, hot and cold die casting

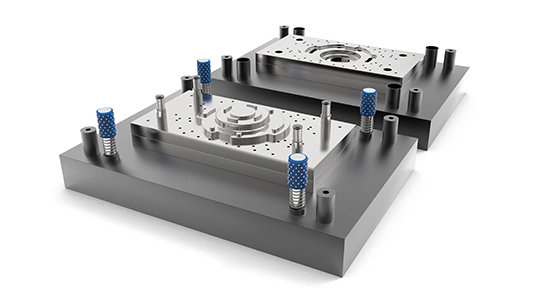

High-precision mold clamping machine, wire-cut edm, high-speed and low-speed wire-cut edm, high efficiency cnc spark machine

Automated production of 40t-750t complex die castings, long service life: 1 million times, hardness: 30-60hr

FDM, SLS, MJF, SLA, SLM

Materials: Choose from 35 types of materials (rigid and flexible plastics, elastomers, metals, etc.)

Surface treatment: Dyeing, Media tumbling, Sandpaper grinding, etc.

Tolerance wn to: ±0.0008 inches (0.020 mm)

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.